Here you can take a good look at what the KS601 looked like when it arrived:

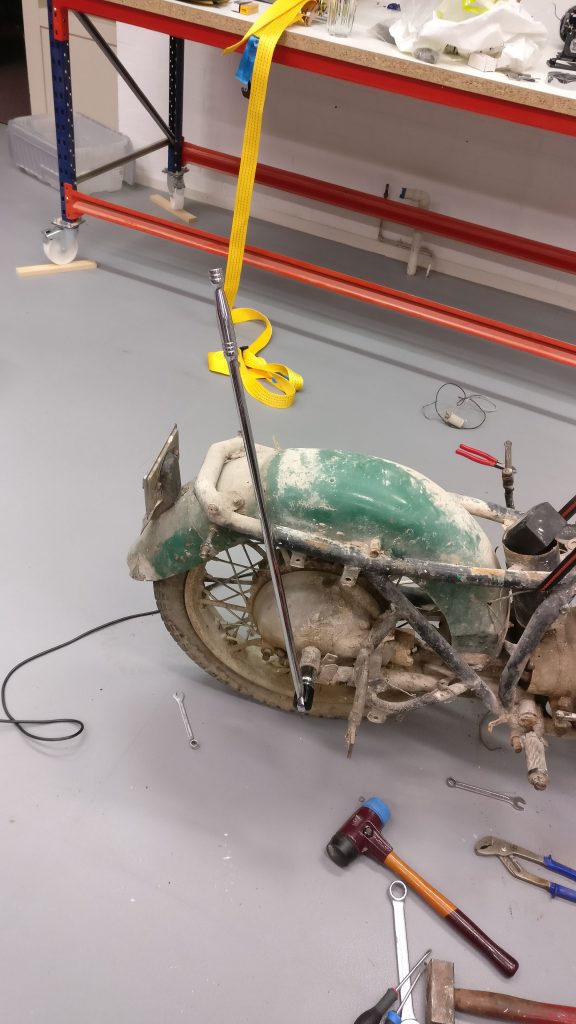

That’s quite a mess, but a challenging project. When stripping the bike for restoration I came across a number of interesting things:

1. There are some strange brackets welded to the frame on both sides. I’m quite intrigued what they would have been used for.

2. While the shock absorbers are missing, the KS601 had plunger suspension. Only the KS601 Elastic, of which 200 were made and shipped to the USA, had a swing arm. So what we’re looking at here is a home made after market swing arm. In a way I have respect for the inventiveness, but it’s not a good looking job. As a result this frame is useless and that presents a problem on registering the bike with the road authority.

3. Apparently the spokes were not strong enough or more stability was needed because metal strips have been welded to the rims along the wheel. I hope these can be removed without damaging the rim too much.

4. You will note a hinge in the kickstarter here which allows it to fold into the side. This is a home made improvement. The original does not have a hinge.

5. The shift lever has been shortened.

6. The foot rest has been welded to the frame.

7. You can’t see it here, but the shift shaft through the gearbox is bent and has cause a crack in the gearbox housing. I’ll post better pictures on this later.

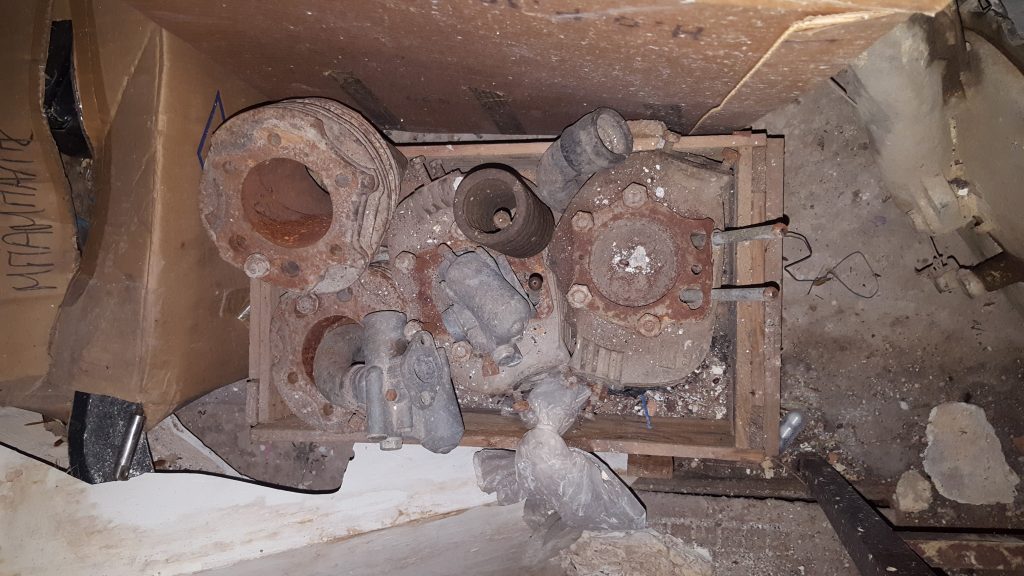

1. The housing of the rear transmission has been completely altered to work with a swing arm. Just compare it to a normal posted below. Internally it may be OK, but the housing is not longer usable.

2. The brake lever is not standard

3. The toolbox is now a tool cylinder.

4. The universal joints are completely work (they move about 3mm) and the transmission shaft has been shortened to work with the new swing arm; that will have to be replaced.

5. The rear mudguard has been shortened too, but the original bit of it was not with the bike. That will mean a creative restoration.

The carburettors are in a really bad shape. You can see the holes in the float chamber! The air slides are so worn and damaged it will take new oversize ones for the carburettors to work – I don’t even know whether they exist… Several of the air adjustment screw had welded knobs on them and the the tops that hold the throttle cable are damaged and one is missing. This will be a very expensive fix.